Custom Thick Gauge Thermoform Packaging

At FormTight, we have over 50 years of combined experience when it comes to your custom thick and heavy gauge plastic thermoforming needs. We truly are your one stop shop and offer superior service which includes everything from conceptual design, engineering, prototyping and in-house tooling throughout the manufacturing process of the finished product.

Capacity and Capabilities

Our thick gauge vacuum forming division includes our 3 stage rotary thermoforming machine, 4-single station thermoforming machines, and two 5-Axis CNC routers that produce precise, high quality finished product in a timely fashion. FormTight has the capacity to thermoform and trim materials that are between .020” - .500” thick. We can handle sheets up to 53” wide x 101” long, which gives us incredible versatility and provides our customers with virtually unlimited options. We can easily source a wide range of plastic materials and the most commonly used in this division (but not limited to) are PETG, HDPE and ABS.

Industry examples of thick and heavy gauge plastic products include:

FormTight Thick Gauge - Triple Station Rotary Machine

At FormTight Inc., we have the capability to custom thermoform a wide variety of plastic parts in our thick gauge division.

This video is an example of a small, medium, and large (Positioner Tray) being thermoformed using a triple stage rotary machine. These trays will be used in the veterinary medical field to transport, hold, and position any size animal during x-rays, including surgical procedures.

Examples of a typical formed part using the vacuum forming or thermoforming method are: cellular shroud covers, medical device trays, housing or safety guards for industrial equipment, panels used for mass transportation such as display enclosures as well as any exterior components.

PETG and HIPS - Domes

PETG - Custom Thick Gauge Product

Thick Clear

Thick Black and Clear

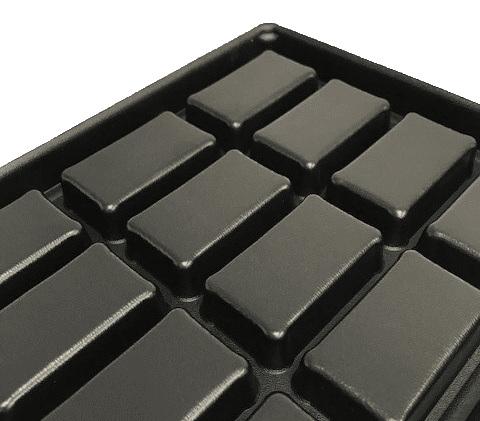

ABS - Custom Thick Gauge Tray